welding bend tester|guided bend test fixture : distributors The back bend test is a type of physical weld testing that is used to determine the quality of the weld metal and the degree of penetration into the root of the Y of the welded butt joint. The specimens used are similar to those .

WEB1 dia atrás · Volatile Vikings slot game currently has a hit rate of 1/3.6 (27.5%). Hit rate is related to the term volatility. Volatility in slots is a spectrum that ranges from Low Volatility to High Volatility. Low volatility is generally understood to refer to slots that pay out regularly, but generally deliver small amounts. High volatility slots are .

{plog:ftitle_list}

Resultado da oed.com is a living text, updated every three months. Modifications may include: further revisions to definitions, pronunciation, etymology, .

The Model BT3 Bend Tester uses a unique method for wrapping the bend specimen around the mandrel. Specimens are forced to conform to the mandrel surface. This is especially useful for specimens from dissimilar metal .The bend test is a simple and inexpensive qualitative test that can be used to evaluate both the ductility and soundness of a material. It is often used as a quality control test for butt-welded joints, having the advantage of simplicity of . The Bend Tester, an 8-ton hydraulic, manual-guided bend test fixture, allows educators to easily conduct destructive weld testing.Uncover the welding bend test, assessing ductility and integrity of welded connections. Explore prep steps, machinery, procedure, and quality benefits.

#welddotcomToday we are going to show you how to pass a bend test with the plate bender we built. If you're a welding student or professional welder chances . The back bend test is a type of physical weld testing that is used to determine the quality of the weld metal and the degree of penetration into the root of the Y of the welded butt joint. The specimens used are similar to those .

Performs guided bend, tensile pull, and fillet break tests; Ideal for educational weld testing environments; . The Fillet Weld Tester, a prominent addition to Sawyer’s esteemed line of weld inspection and tensile testing equipment, .Uncover the welding bend test, assessing ductility and integrity of welded connections. Explore prep steps, machinery, procedure, and quality benefits. Welding Bend Tests: Understanding Bending in Welding Inspections

difference between volumetric coulometric karl fischer titration service

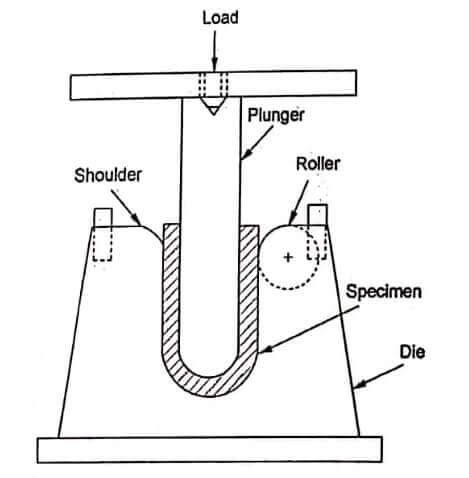

W-6810 | Guided-Bend/Weld Bend Test Fixture. Guided-Bend / Weld Bend Test Fixture, Adjustable Span for "U" bend tests of plane plate or welded flat specimens. Fixture consists of a t-slot base with adjustable span supports supported by two tie rods. Fixture specifications: Span - 0 to 254 mm (10.0 in) Specimen width - up to 76 mm (3.0 in)

The BEND TEST! One of the tests used to determine the soundness of weld metal is a bend test. A bend test can take a few forms and may have to meet different requirements. For the purpose of this short piece of information, we will talk about the “Guided Bend Test” as opposed to the “Free Bend Test”. Here is a closeup video of a . B1. Longitudinal Guided-Bend Test (See Part A1, section 7.6, Fillet Weld Root Bend Test.) 1. Scope 1.1 This section covers the bend testing of fillet welds. The standard gives the requirements for guided bend test specimen preparation, test parameters and testing proce-dures, but does not specify the requirements or accep-tance criteria. Welders use a welding bend tester to check the welds they make for soundness and to identify any flaws. A welding bend tester is a simple tool that consists of a metal plate with a hole in the center and two clamps. The welder places the welded piece in the test jig, pulls it tight between the clamps, and then bends it. By watching how the weld .

This video shows you how to first perform a visual examination on a groove weld according to the AWS D1.1 Structural Steel welding code. It then shows you h.

Additional information on the mechanical testing of welded joints may be obtained from the AWS Welding Handbook, Ninth Edition, Volume 1, which describes selected weldability test methods. AWS B4.0:2016, Standard Methods for the Mechanical Testing of Welds, is the eighth edition of the document initially published in 1942.Sawyer’s 55 Ton Bend and Tensile Tester. Model 273-55. For weld certification and qualification, Sawyer’s line of weld inspection and tensile testing equipment is hard to beat, and the 55 Ton Guided Bend and Tensile Tester is no exception. It provides accurate, dependable weld-quality testing, whether used in the shop or in the field. .This Item: Fischer Pneumatic Weld Bend Tester. ,184.00) Description; Resources; Description. The Model BT1C is very portable and is intended for applications where the material and thickness to be bent are usually the same. While this model is not adjustable for different radii, it can be converted by interchanging additional parts.

4. Back Bend Test. This is a physical weld testing designed to ascertain the quality of the weld metal and the extent of penetration into the root of Y of the butt joint after welding. The sample or specimen used for testing is similar to the free bend test except they are bent with the root of the weld towards the tension side, or outside.This machine was designed and developed by Triangle Engineering to bend a welded metal specimen into a 180 degree "U" shape, thereby subjecting the weld deposit to extreme tension, commonly referred to as a bend test. The full range of ferrous and nonferrous bend test requirements of A.S.M.E. Section IX and A.W.S canThe W-50 Weld Tester is a destructive weld testing machine that incorporates compression, tensile, and bend testing in one complete unit. The W-50 is an invaluable asset to any training facility or commercial company that requires weld qualification. The W-50 can do all the key destructive tests as specified by AWS, ASME, and API. .

Fillet Weld Tester, 25-ton, hydraulic H-frame press for fillet-welded "T" joints made from ½" max. thick steel for AWS D1.1 and other codes. 937-754-1750 [email protected] Home

During the bend test, the material containing the weld is supported on both ends by the test fixture, while a load is applied at its center point. Materials Testing System. For ASTM E290 testing we recommend using an Industrial Series .The W-50 Weld Tester is a piece of destructive weld testing equipment that incorporates compression, tensile, and weld bend testing in one complete unit. This is an invaluable asset to any training facility or commercial company that requires weld qualification. The Watts Process Machinery W-50 can do all the key destructive tests as specified by AWS,

iso view in bending position plan view in bending position weld coupon shop vice. iso view shop vice. wraparound guided bend test jig rev. 1 - 180905 note:use at your own risk. aws d1.1: 2015, fig. 4.12 - for material 3 8" thick and yield strength of 50 ksi (345 mpa) and under. csa w47.1 - 09, fig. 18: for material 3Sawyer Weld Testing Equipment Sawyer engineering and workmanship matched with substantial hydraulics on our guided bend and tensile testers make these units the top choice for technical colleges, welding shops, and pipeline inspection. Our weld testing equipment is heavy duty yet portable to allow on-site testing of welders. We have three iron horse models sure to meet .

before or after bending) or dressing bent specimens, will result in the immediate loss of bend testing privileges and failure of the welders. Approx 180º . Acceptable Bend Test Unacceptable Bend Test . The CWB Group ontinue towill c perform the evaluation of the bend test specimens.Welcome to the new Weldbend website! Please take a moment to browse the site and become familiar with the new layout. We would appreciate any feedback regarding your experience on our site and comments can be sent here.. For over 60 years, Weldbend has produced the highest quality domestically manufactured carbon steel fittings and flanges in the industry

welding bend test procedure pdf

Weld quality inspection with the RealCareer Bend Tester. Help users prepare for and safely conduct destructive, guided bend tests in a classroom or welding . What is a Root Bend Test in Welding? The root bend test is a welding test in which the weld root is on the convex surface of a specified bend radius. This test is used to evaluate the mechanical and metallurgical properties of a weld joint. The root bend test is often used in qualification tests for welding procedures and welder performance. The bend test uses a test specimen that is bent in three-point bending to a specified angle. In the Guided bend test the test specimen is wrapped around a former of a given diameter as per the test specification.. The guided bend test is the most common test method used for welding procedure qualification (PQR) and welder performance qualification .Tensile testing cannot be used to determine bendability, since these are different failure modes. Failure in bending is like other modes limited by local formability in that only the outermost surface must exceed the failure criteria.. ASTM E290 A-26, ISO 7438 I-8, and JIS Z2248 J-5 are some of the general standards which describe the requirements for the bend testing of metals.

hach titralab kf1000 series volumetric karl fischer titrator 3 980 service

This test involves bending a test specimen with a welded butt joint to a specified bend radius using plunger-type or wraparound bend test machines. To make face bend tests, the tension force is applied to the weld face. To make root bend tests, the tension force is applied to the weld root.

weld guided bend test equipment

weld bend testers for sale

Resultado da 29 de jun. de 2023 · 78.87%. Boca Juniors x Monagas SC Resultado ao Vivo, Estatísticas & Equipas 29/06/2023 Copa Libertadores da América .

welding bend tester|guided bend test fixture